Lesson

6: Fiber Optic Testing

Objectives:

From this lesson you should learn:

What needs testing in fiber optics

How to trace fibers and locate faults with a visual fault

locator

How to inspect and clean fiber optic connectors

How to measure optical power

How to measure insertion loss with a light source and

power meter

Testing

cable plants and patchcords

3 Methods of

setting a "0dB" reference

Factors

affecting measurement uncertainty

How to use an

OTDR properly

Setting up OTDR test parameters

Interpreting

OTDR traces

Factors

affecting OTDR measurement uncertainty

Tools

And Components Needed

Visual

Fault Locator

Fiber optic inspection microscope with adapters

for connectors being inspected - typically 2.5mm

ferrule (SC/ST/FC) and 1.25mm ferrule (LC)

Fiber optic power meter with

adapters for connectors being inspected

Fiber optic light source appropriate for fiber and

cables being tested (850/1300nm LEDs for MM,

1310/1550nm laser for SM)

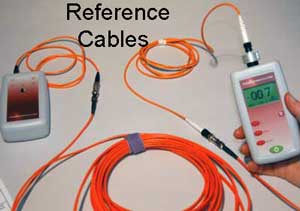

Jumper cables for use as reference test cables appropriate

for fiber and cables being tested (2+m

long preferred)

OTDR appropriate

for fiber and cables being

tested (850/1300nm for MM,

1310/1550nm laser for SM)

Launch and receive cables for OTDR testing

(typically >100m, depending on the OTDR

resolution and preferably from the same fiber)

Consult the Workbook

section on Testing for equipment needed

or refer to the CFOT

Certification Lab Manual

Introduction

Fiber

optic testing is the least well understood aspect of fiber

optic installation. That's what manufacturers say and

exactly what we see on FOA certification exams. Granted

fiber optic testing is not simple (mostly because of the

complexity of the instruments) but it is straightforward.

The principles are easily learned and if applied in

everyday use, they become habits for the competent

installer.

Recognizing the complexity of fiber optic testing, the FOA

devotes a chapter (Chapter 8) in our basic fiber and OSP

textbooks and has created a complete textbook on fiber

optic testing that expands on every subject in testing and

covers some advanced topics that are not in our basic

textbooks. If you are doing fiber optic testing, we highly

recommend you get a copy of this book for reference. FOA

Reference Guide To Fiber Optic Testing.

This lesson covers the basic fiber optic tests used to

test components and installed cable plants. It includes

six separate exercises that will each take some time to

complete.

Make certain

before you begin each exercise that you have everything

you need - tools, test equipment and components. Refer to

the check list on Lesson 2.

Safety

|

Please

Note: This is not the usual online

course - it is intended to guide you as

you learn new skills - the "hands-on"

skills needed to install optical fiber

cable plants. It involves using tools

and components in a realistic manner.

Some of the processes here can be

hazardous, like working with sharp

scraps of optical fiber and chemicals.

In

Lesson 1 you should have familiarized yourself

with the safety procedures - follow them all

the time. Do not work with fiber without eye

protection and a proper work area that is easy

to clean up.

Always wear safety glasses when doing

any of these exercises and dispose of

all scraps properly. |

Follow the safety procedures learned in lesson 1 with some

special warnings for testing. Do not use a microscope to

inspect connectors until you have tested the output of the

connector with a power meter as the microscope can focus

all the light into your eyes. Preferably use a microscope

with a IR filter to remove potentially dangerous light.

Beware of VFLs (visual fault locators) which have high

output in the wavelength of light where eyes are very

sensitive. Do not look into the VFL connector and look at

the output of cables being tested with a VFL at an angle

to see if the light is too bright. The output of laser

sources may be high and they are invisible to the human

eye. Follow the general polify of testing fibers with a

power meter before looking at the end.

Background

Review

This "skills" course assumes you have

knowledge of fiber optic termination and

splicing. If you are new to fiber optics, you

should first review the section of the FOA

Guide on Testing, read the Workbook

section on Testing and/or complete the Fiber

U Basic Fiber Optics: Testing

course before attempting the hands-on

exercises here.

Hands-On

Lab Instructions

Download the Workbook section on Testing and the VHO

tutorials on Insertion Loss and OTDR. Watch the videos

and/or read the references on the test you have

available for practice. The VHO

"Virtual Hands On" Tutorials take a "step-by-step"

approach to the hands-on processes covered in this

self-study program and the videos will show the

processes in motion. The "Insertion Loss Simulator"

uses a virtual source and power meter to test

a cable plant, step-by-step. They are both a good

way to teach yourself the processes here - watch the

video for the overview then follow the steps in the

VHO web pages.

Additional

references are given for each of the exercises below.

Hands-On

Assignments:

After reading the workbook section and VHO tutorial

and watching the videos, complete these exercises using

all the cable types available to you.

As you finish each section, fill in the worksheet in

the back of the Workbook on Testing. Your completed

worksheets are the records of your having successfully

completed the exercises.

Visual Tracing And

Fault Location

Tools and equipment

needed

Visual

fault locator (VFL, laser based)

Visual tracer (LED flashlight based)

Patchcords and cables, both SM and MM

Warning:

VFLs can be powerful enough to be an eye hazard.

Do not look directly into the VFL connector or the

end of a fiber illuminated by a VFL. Instead, aim

the end of the fiber at a light colored object and

look for the laser light.

YouTube

Video: FOA

Lecture 13: Testing Fiber Visually,

FOA

Lecture 21 Visual Fault Locator

Demonstration

Online

Guide: Visual

tracing & fault location

Connect a cable to the VFL or visual tracer, and

check continuity by seeing if the fiber transmits

light. Compare the amount of light transmitted

through SM and MM fiber.

While the cable is connected to the VFL, put bends

in the fiber as shown above (yellow jacket SM fiber

shown) and note the loss in the cable. Can you tell

a difference in the output of the fiber at the

connector? Why?

If you have a cable (preferably

yellow jacket SM fiber) you are willing to

damage, break the fiber and see what the

cable looks like.

Visual Inspection

With A Microscope

Tools

and equipment needed

Fiber

optic inspection microscope, either

optical or video (shown)

Fiber

optic cleaning supplies

Patchcords

and cables, both SM and MM

YouTube

Video: Visual

Inspection of

Connectors With A

Microscope,

FOA

Lecture 13: Testing

Fiber Visually

Online

Guide: Microscope

Inspection of

Connectors

Inspect the connectors on the patchcords

or cables with the microscope immediately

upon removal of the dust caps. What do you

see?

Clean the connectors and inspect again. Is

the ferrule surface clean? If not clean

again. Use both wet and dry methods.

Replace the dust cap, remove it and check

the connector again. Was it still clean?

Touch the end of the connector with your

finger and inspect it. Clean and inspect

again.

Drop a connector on a carpet (perhaps the

one on the cable you broke for the VFL

exercise) and inspect

it. Clean and inspect

again.

Measuring Optical

Power

Tools

and equipment needed

Fiber

optic light source and power meter,

adapters for connectors used on patchcords

and cables

Fiber

optic cleaning supplies

Patchcords

and cables, both SM and MM

YouTube

Videos: FOA

Lecture 14: Testing Optical Power

Online

Guide:

Measuring

Optical Power,

Units of

Measure (dB, dBm),

Calibration and

Uncertainty in Fiber Optic Power Measurements

Turn on the source and let the output stabilize.

Turn on the meter and familiarize yourself with the

controls. Put the meter on dBm and set the

wavelength to the wavelength of your source.

Measure the power output of the light source. Stress

the cable by putting bends in it (as with the VFL

exercise) and note the differences. Change the

wavelength setting to another wavelength and note

the changes. Why does the measured power change?

Measure the output of a 850nm or 1300nm LED source

with both SM and MM fiber? What changes do you note?

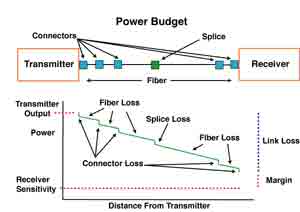

Loss Budget

YouTube

Videos:

FOA

Lecture 26, Loss Budgets

Online

Guide:

What

Loss Should You Expect?,

Link

Loss Budgets And Power Budgets

Before measuring loss, it is important to calculate

a loss budget so you have an idea of what the loss

should be if the components are in good condition.

A: Calculate the loss budget for a long distance

network: singlemode fiber, 75km long, 14 splices, LC

connectors on each end. Fiber attenuation at 1550nm

is 0.21 dB/km, splices average 0.05dB and connector

losses are 0.3dB/km.

B:

Calculate the loss budget for a metropolitan

network: singlemode

fiber, 6.5km

long, 2 splices, one intermediate patch

panel plus LC connectors on each end. Fiber

attenuation at 1310nm is 0.40 dB/km, splices

average 0.05dB and connector losses are

0.3dB/km.

C:

Calculate the loss budget

for a LAN backbone: OM3

fiber 210meters long, no

splices, two intermediate

patch panels plus SC

connectors on each end.

Fiber attenuation at 850nm

is 3.10 dB/km and connector

losses are 0.5dB/km.

Answers

below.

How to calculate loss

budgets easily: FOA

has a free loss budget

calculator for iPhones and

iPads.

Calculate loss budgets for a cable plant you can

make from the cables you have for the exercises.

Remember you need two patchcords for reference test

cables.

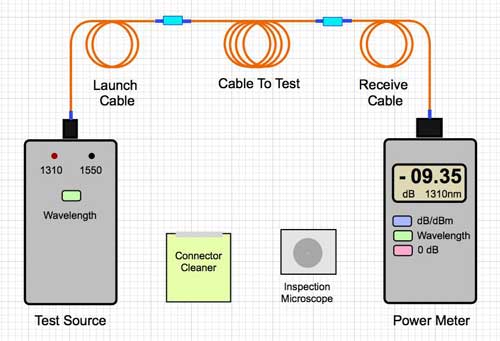

Single Ended Loss

Test

Tools

and equipment needed

Fiber

optic light source and power meter,

adapters for connectors used on patchcords

and cables

Fiber

optic cleaning supplies

Patchcords

and cables, both SM and MM, at least

three of the same type for testing (2

reference test cables and one cable to

test) and mating adapters

YouTube

Videos:

FOA

Lecture 16: Insertion Loss

Testing ,

Online

Guide:

Installed

Cable Plant

Testing (FOA-1,

OFSTP-7 & 14),

FOA

Standard FOA-1,

What

Loss Should You

Expect?,

VHO:

Insertion

Loss

If

you are not familiar with the operation of

these instruments read the manuals and work

with the instrument until you know how to

change test parameters and interpret the

display.

Attach one cable

to the source which will be the reference "launch

cable" and measure the output with the power meter.

Set the power meter on the 'dB" range and push the

button to zero the reading, setting the "0dB"

reference.

Using a mating adapter, attach a second cable (the

cable to test) to the launch cable and measure the

loss. What are your measuring?

Reverse the cable to test and measure again. Is the

loss different? Why?

Test other cables and record the results.

Modify

the launch conditions with a mandrel wrap on

the launch cable. Make a measurement of a

cable under test and record the results.

Wrap 5 turns of the cable around a 25mm (1

inch) mandrel (any round object will work)

and repeat the test (set 0dB reference,

check connection to receive cable, insert

cable to test and record data.) Are the

results different? Why? Repeat the test with

a cable plant made from several cables and

note the results.

Use a 62.5/125 micron cable for a launch

cable and test a 50/125 cable. What is the

result? Use a mandrel wrap on the launch

cable and repeat the test. What is the

result? Use the same 62.5/125

micron cable launch cable to

test a WM cable. What is the

result?

Use

a 50/125 micron cable for a launch

cable and test a 62.5/125 cable.

What is the result?

Double Ended

Loss Test

Tools

and equipment

needed

Fiber

optic light source and power meter,

adapters for connectors used on patchcords

and cables

Fiber

optic cleaning supplies

Patchcords

and cables, both SM and MM, at least

three of the same type for testing (2

reference test cables and one cable to

test) and mating adapters. The cable to

test for the exercises should be long

enough to also be used in the OTDR test

exercise as you will compare the test

data for each method.

YouTube

Videos:

FOA

Lecture 16:

Insertion Loss

Testing ,

Online

Guide:

Installed

Cable Plant

Testing

(FOA-1,

OFSTP-7 &

14),

FOA

Standard FOA-1,

What

Loss Should

You Expect?,

VHO: Insertion

Loss.

Insertion

Loss Simulator allows you to use

a virtual source and power meter to test a

cable plant, step-by-step.

Use it with your source and meter to test insertion loss

or do the test virtually using the simulator. Both

singlemode and multimode versions are available and you

see how Loss Budgets are used in testing.

Testing cable with the insertion loss simulator

If

you are not familiar with the

operation of these instruments read

the manuals and work with the

instrument until you know how to

change test parameters and interpret

the display.

Attach

one cable to the source which will be the reference

"launch cable" and measure the output with the power

meter. Set the power meter on the 'dB" range and

push the button to zero the reading, setting the

"0dB" reference.

Using a mating adapter, attach a second cable (the

cable that will become the receive cable) to the

launch cable and measure the loss. What are your

measuring? DO NOT RESET the "0dB"

reference.

Detach the two cables and insert a cable to

test using another mating adapter and

measure the loss. What are your

measuring?

Reverse the cable to test and measure again. Is the

loss different? Why?

Change

the reference method to a "two cable

reference," i.e. set the zero dB reference

with both a launch and receive cable and

repeat the test on the same cable you just

tested. Record the results. What is

different and why?

Change

the reference method to a "three

cable reference," i.e. set the zero

dB reference with both a launch and

receive cable and a third reference

cable between them and repeat the

test on the same cable you just

tested. Record the results. What is

different and why?

Compare your tests of the same cable

with one, two and three cable

reference methods.

Test other cables and record the results.

Modify the launch conditions with a mandrel wrap on

the launch cable. Make a measurement of a cable

under test and record the results. Wrap 5 turns of

the cable around a 25mm (1 inch) mandrel (any round

object will work) and repeat the test (set 0dB

reference, check connection to receive cable, insert

cable to test and record data.) Are the results

different? Why? Repeat the test with a cable plant

made from several cables and note the results.

Use a 62.5/125 micron cable for the launch and

receive cable and test a 50/125 cable. What is the

result? Why?

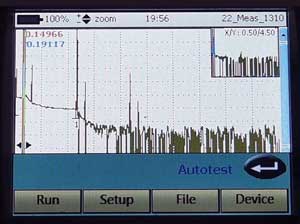

OTDR

Testing

Tools

and equipment

needed

OTDR

with adequately long launch and receive

reference test cables, preferably of the

same fiber and equal lengths.

Fiber

optic cleaning supplies

Cables

of sufficient length to test with an

OTDR, both SM and MM if the OTDR tests

both, and mating adapters

(Optional - use the FOA OTDR

Simulator or Fiberizer

to simulate the test if you do not have

an OTDR or adequate fiber to test.)

YouTube

Videos: FOA

Lecture 17: OTDR Testing,

FOA

Lecture 18: OTDR Setup,

FOA

Lecture 19: OTDR Measurement

Uncertainty

Using

An OTDR (Hands-On)

Online

Guide:

OTDR

testing ,

Frequently

Asked Questions about OTDRs

VHO:

OTDR.

Software

Download: OTDR

Simulator

With

an OTDR

If you are not familiar with the operation of this

OTDR read the instrument manual and operate the

instrument until you know how to set parameters

manually, take traces and analyze them using both

"two-point" and "LSA" methods.

Connect a launch cable to the OTDR and set the OTDR

in the manual mode. Choose a range appropriate for

the launch cable, typically the shortest range for

the OTDR. Set the pulse width to the shortest option

and averaging to a short time period or ~32-64

cycles. Set the wavelength to 850nm for MM or 1310nm

for SM. Take a trace of the launch cable. Measure

how long it takes for the trace to return to the

baseline (the "dead zone"). Change the pulse width

to longer options and measure the changes to the

length of the dead zone.

Attach a cable to test to the launch cable and reset

the OTDR to the shortest pulse. Take a trace. Can

you see the end of the fiber in the cable under test

or is it too noisy? If it is too noisy, go to a

longer OTDR pulse or average for a longer time until

you an clearly see the end of the cable under test.

Using the two marker method, measure the loss of the

connection between the launch cable and the cable

under test and the

attenuation of the fiber in the cable under

test. Record the

results (including saving the traces for later

comparison.) Repeat the tests using the LSA methods.

Record the results and compare to the two marker

method. Are there differences? Why? Measure the

reflectance of the connection between the launch

cable and cable under test. Can you measure the loss

of the connector on the far end of the cable under

test? If not, why not? Change the OTDR to the

"autotest" mode and repeat the measurement. Compare

the results. What is different?

Do you see any "ghosts" in the traces?

Attach a receive cable to the far end of the cable

under test. Now using the two marker method, measure

the loss of the connections on either end, the

attenuation of the fiber in the cable under test and

the total loss of the cable under test including the

connections on each end. Record this data for

comparison.

Repeat

the tests using the LSA methods. Record the results

and compare to the two marker method. Are there

differences? Why?

Reverse the cables

(remove the launch cable from the OTDR and connect

the OTDR to the open end of the receive cable

without disturbing the other connections) and repeat

the tests. Record

the results and compare to the two marker

method. Are there differences? Why? Change

the OTDR to the "autotest" mode and

repeat the measurement. Compare the

results. What is different?

Record the

traces at one wavelength and test at the

other (e.g if you have MM traces at 850nm,

take a new trace at 1300nm, or SM at 1310nm,

change to 1550nm.) Compare the traces. Is

the fiber attenuation different? How about

connections?

With The

OTDR Simulator

Install the OTDR simulator on your PC. Open

the program (ignore the warning that it is

looking for the hardware of the PC OTDR it

was written for.) Follow the manual to

understand how the OTDR Simulator works.

Go to the folder "Parameter Traces" and open

the traces w-850.sor and w-1300.sor and

compare them. Each set of files with the

same beginning to the name are meant to be

compared. Do that with each set to see what

happens when you change parameters on the

setup menu of the OTDR. The folders Traces

and Span Traces include more traces to

analyze.

Test

Your Comprehension - Online

Quiz On Testing

Have

you completed the Workbook worksheets that are the

records of your having successfully completed the

exercises?

Get a "Certificate

of Completion" When You Complete The Course

After you complete all six lessons of the Fiber U Basic Skills Lab

Fiber Optics online self-study course, you can

now take an online exam and, when you pass the

exam, get a "Certificate of Completion" for this

course. You should complete all lessons

including taking the quiz ("Test Your

Comprehension") at the end of every lesson. When

you think you are prepared, you can take an

online exam for a nominal fee ($20) which will

give you a "Certificate of Completion" for

this course.

Take the Test to Get Your

Certificate of Completion For This

Course

Loss Budget Answers:

A: Calculate

the loss budget for a long distance network:

singlemode fiber, 75km long, 14 splices, LC

connectors on each end. Fiber attenuation at

1550nm is 0.21 dB/km, splices average 0.05dB and

connector losses are 0.3dB/km.

Loss = 75km x 0.21dB/km (=15.75dB) + 14 splices x

0.05dB (=0.70dB) + 2 connections X 0.30dB

(=0.60dB) = 17.05dB

B:

Calculate

the loss budget for a metropolitan

network: singlemode

fiber, 6.5km

long, 2 splices, one intermediate patch

panel plus LC connectors on each end.

Fiber attenuation at 1310nm is 0.40 dB/km,

splices average 0.05dB and connector

losses are 0.3dB/km.

Loss

= 6.5km x 0.40dB/km (=2.60dB) +

2 splices x 0.05dB (=0.10dB) + 3

connections X 0.30dB (=0.90dB) =

3.60dB

C:

Calculate

the loss budget for a LAN

backbone: OM3 fiber

210meters long, no

splices, two intermediate

patch panels plus SC

connectors on each end.

Fiber attenuation at 850nm

is 3.10 dB/km and

connector losses are

0.50dB/km.

Loss

= 0.21km x 3.10dB/km (=0.65dB) +

4 connections X 0.50 dB

(=2.00dB) = 2.65dB

Return

to Fiber U Basic Skills Lab Lesson Plan

|